"Physics-informed Machine Learning for Metal Additive Manufacturing"

Raghav Gn. (Gnanasambandam)

Industrial and Manufacturing Engineering

FAMU-FSU College of Engineering

Wednesday, Nov 5, 2025

- Nespresso & Teatime - 417 DSL Commons

- 03:00 to 03:30 PM Eastern Time (US and Canada)

- Colloquium - 499 DSL Seminar Room

- 03:30 to 04:30 PM Eastern Time (US and Canada)

Abstract:

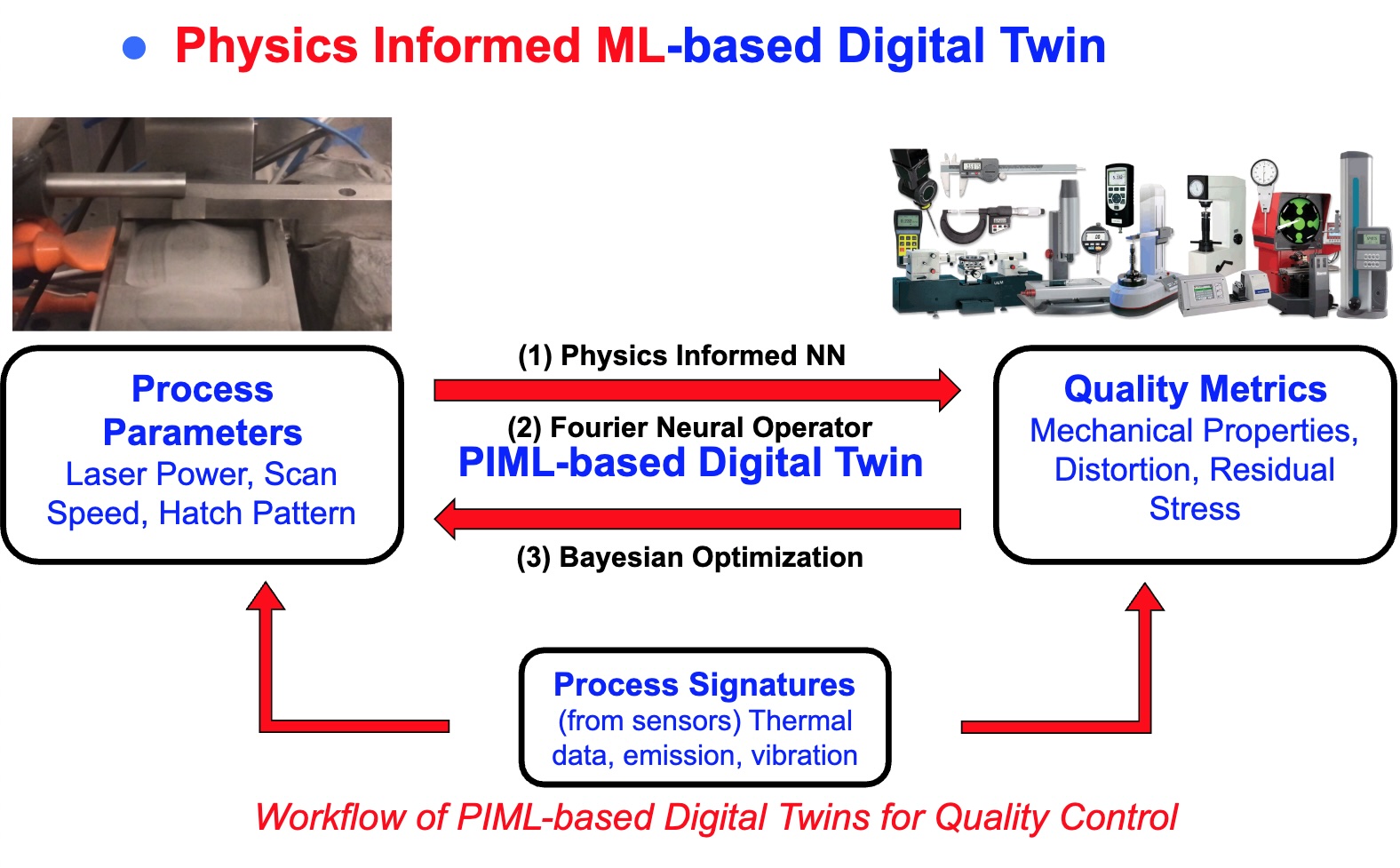

Metal additive manufacturing (AM, or 3D printing) is an emerging technology for producing parts with virtually no constraint on the geometry. AM builds a part by depositing materials in a layer-by-layer fashion. Despite the benefits in several critical applications, quality issues are one of the primary concerns for the widespread adoption of metal AM. This talk will discuss three methods for improving the quality of metal AM processes. (1) Physics Informed Neural Networks (PINNs): Development of a novel activation function and a disjoint architecture enabled fast and accurate physics-based simulations of two metal AM processes - laser powder bed fusion and additive friction stir deposition processes. (2) Fourier Neural Operators (FNOs) are useful in accelerating some of these simulations for a specific type of process optimization. (3) Bayesian Optimization with Deep Gaussian Process for optimizing the process parameters with adaptive experimentation/active learning.